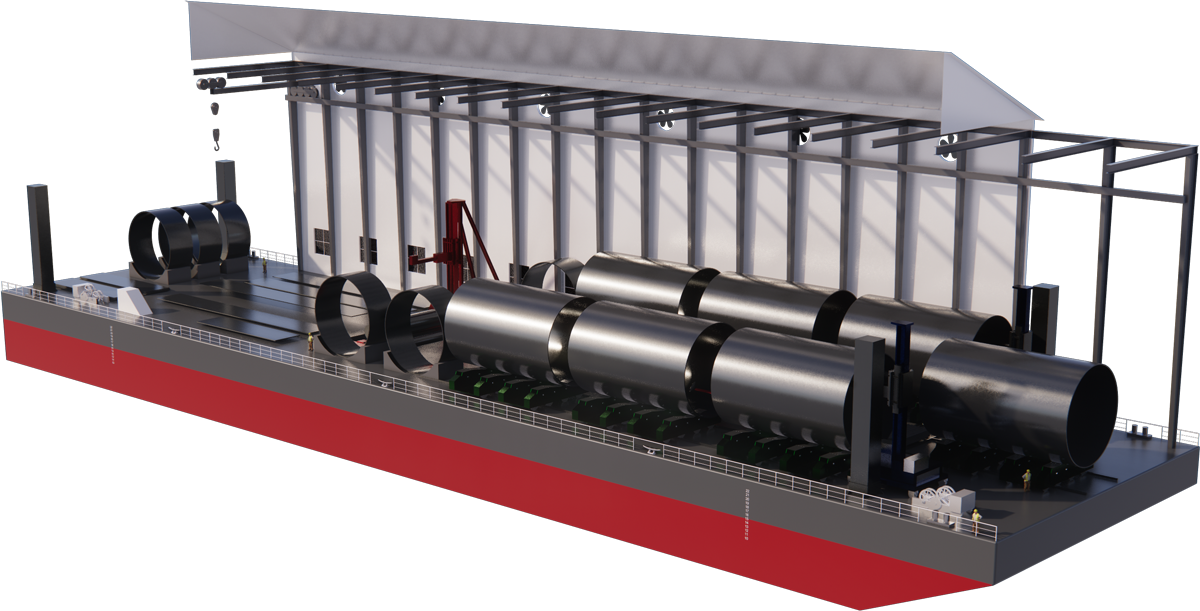

Mobile Pipe Mill

BMS 1888

U.S. designed for the offshore wind market.

Easily constructed at any yard with the capacity.

Eliminates the need for a full scale shore-side fabrication facility.

Can be relocated to any project area.

Easily scalable to meet the requirements of the project.

Easy to load materials and offload constructed pipe sections by crane.

Fast and cost effective on-site steel pipe manufacturing.

Connects to shore power for operation, or can be supplied by a dedicated power barge.

Design specifications

|

Length overall |

400 ft |

|

Breadth |

100 ft |

|

Draft |

15 ft |

|

Depth |

25 ft |

Technical specifications

|

Type Classification |

Deck Barge |

|

|

Dimensions |

Length overall |

400 ft |

|

Breadth |

100 ft |

|

|

Draft |

15 ft |

|

|

Depth |

25 ft |

|

|

Equipment |

2 x Long Seam Weld Station 1 x Roller Arm 3 x Welding Manipulator-Arm for 10' Rolled Plate 2 x Stabbing Station 2 x Stringer Weld Station 2 x Back Weld Station 2 x Welding Manipulator-Arm for Back Weld 1 x Overhead Bridge Crane and Gantry System 4 x 60' Spud 2 x Spud Winch |

|

|

Steel Capacities |

10' x 40' Steel Plate Storage |

|

|

Capacities

|

Ballast |

797,400 gal |

|

Fresh Water |

266,300 gal |

|